Seismic Testing of Fire Stopping Products

Download The Full Article Here Introduction It feels like yesterday, but most of us remember exactly where we were and what we were doing when

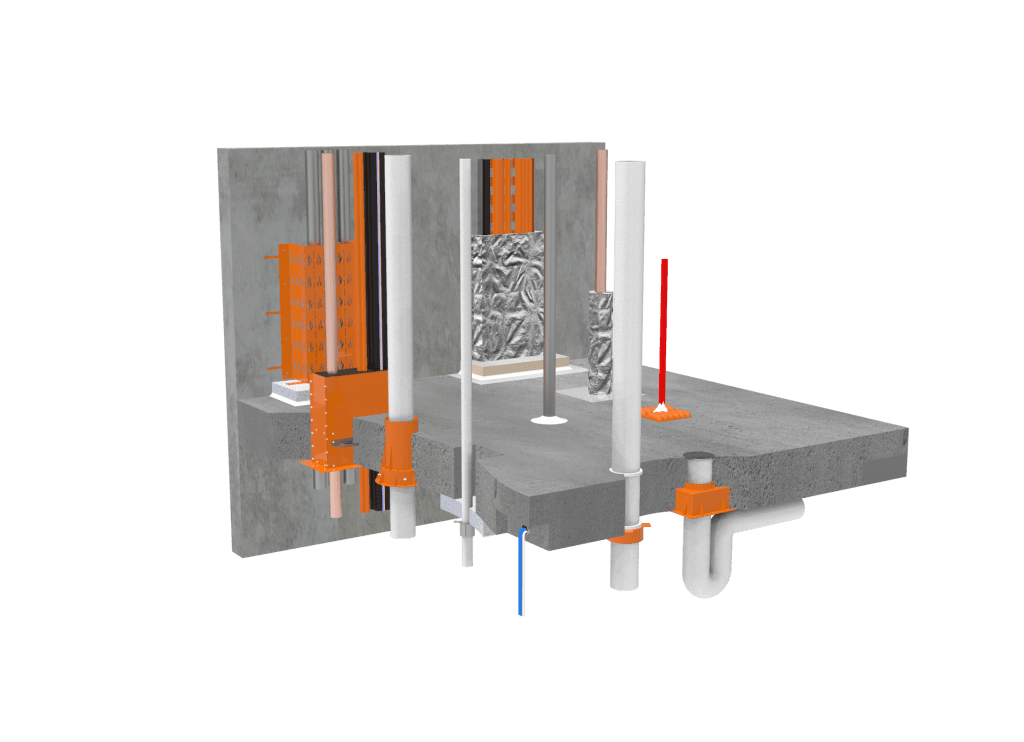

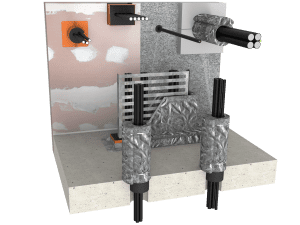

Concrete slabs are the most common type of fire rated floor used in the Australian building industry due to their inherent strength and fire-resistant properties.

This page lists the tested passive fire penetration systems currently available to maintain the fire resistance level (FRL) of service penetrations through concrete floors systems with both cast-in options as well as retro-fit systems for core holes and larger openings.

We have a wide range of resources available for every product and system to ensure that you’re choosing the right fire stopping solution for your needs.

FRL Tables, installation instructions, benefits, applications, and more are all available in our comprehensive manuals, for all systems and products.

Retrofit solution ideal for

PVC Pipes ranging 50mm to 150mm

Cast-in fire-stopping solutions for floor waste

applications, with approvals up to 4 hours across

a huge range of common pipe types and sizes.

Fire-rated acrylic sealant perfect fire-stopping

for metal pipes and electrical cables/tray

Penetration protection with

FyrePLUG Fire-rated pillows

Australian Made special cement-based mixture

formulated specifically for fire rating applications,

Tested in numerous configurations and with a multitude

of service penetration types providing FRLs up to -/240/240

(system dependent)

Penetration protection for copper

pipes in floors and walls with TWRAP

Penetration protection for cable

trays in floors with TWRAP

Penetration protection with FyreBATT

Quicker installation option for wrapping

large metal pipes. FRLs up to -/120/120

for large metal pipes

High-performance fire-rated board

for floor and wall penetrations

on either side of the slab

High-performance fire-rated board

for floor and wall penetrations

on either side of the slab

Intumescent lined system designed to prevent

the spread of fire through service penetrations.

Allows multiple and mixed services to pass through

one opening, eliminating the need for 200mm

separation between adjacent service.

Provides a full range of solutions for use in both

stack pipe and floor waste applications,

with up to 4 hours across a huge range'

of common pipes types and sizes.

Small retrofit collar for plastic

services like conduits and PEX

Intumescent sealant for cables and small pipes

We’re proud to be making passive fire protection easier every single day. Our extensive range of resources have been written, developed, or sourced by Trafalgar Fire’s experienced team of passive fire professionals to help you better understand our systems, products, and the passive fire industry as a whole.

Check out the latest installation and product videos, articles, and case studies for Concrete Floor Systems.

Download The Full Article Here Introduction It feels like yesterday, but most of us remember exactly where we were and what we were doing when

Control, movement or expansion joints are an important part of good building practice. They are used to allow for movement and expansion and stop unsightly

The most basic way to understand passive fire protection is that we install on-site in the same manner that a successfully fire-tested SYSTEM was installed.

Everyone knows things are changing but no one seems to know why. I am being asked more frequently, in fact, several times each day, especially

Seismic Testing of Fire Stopping Products

Download The Full Article Here Introduction It feels like yesterday, but most of us remember exactly where we were and what we were doing when

Trafalgar’s technical team met with the builder’s Quality Assurance Manager and the mechanical contractor and discussed potential options, with the FyreBOX Cast-In being proposed as

We are constantly looking for ways to improve our methods of service delivery. We would really appreciate it if you could rate your experience {or/at our website/premises} today.

Trafalgar takes privacy seriously, so any information that you provide here will not be used for marketing purposes, and it will not be shared with third parties.