John Rakic

John Rakic is the proud Owner and Managing Director of Trafalgar Group with over 20 years of experience in the passive fire industry.

Passive fire compartments, fire containment barriers and separate fire cells (or zones) are well known in the industry. For those who don’t know, the principles are relatively simple; if a fire breaks out in one part of a building, we want to contain the fire to that part of the building using fire walls, floors, ceilings, shafts and other so called “fire stopping” products and systems. Most passive fire protection systems have detailed fire test methods, allowing fire ratings to be deduced for regulatory purposes. The required Fire Resistance Levels (FRLs) are provided in the National Construction Code (NCC), based on the class of building (use) and type of construction (rise in storeys).

This article deals with so called “cavity barriers” and is a compilation of my research into the application of SIDERISE perimeter fire stop and cavity barrier systems, for specification, design advice and ultimate sale here in Australia by Trafalgar Fire, my company.

This is just a snippet of the full article. To read the entire article, download the pdf today.

Table of Contents

What Are “Cavity Barriers”?

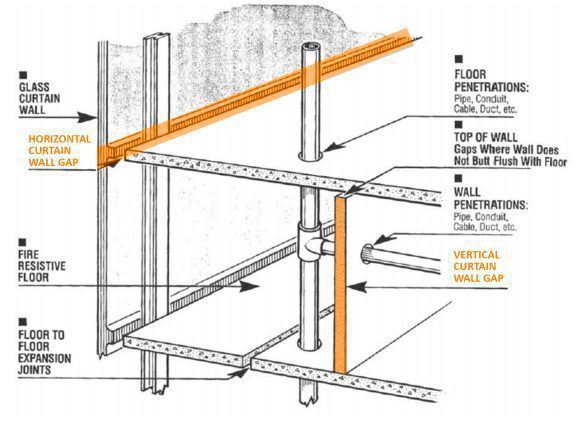

The concept behind “cavity barriers” isn’t very complicated; they’re a fire and smoke containment system used to stop the spread of fire and smoke through cavities. The most prevalent and widely used cavity barriers are used to stop vertical fire and smoke spread within the cavities formed around the perimeter of an external building envelope. These come in two forms:- Horizontal Cavity Barriers—used to seal the edges of the horizontal internal floor slabs, and

- Verticle Cavity Barriers—used again to seal the vertical floor to floor edges to divide the cavity on one given floor vertically into predetermined zones.

Why do we need Cavity Barriers?

There are three very different “cavity barrier” applications for different construction types used here in Australia:- Curtain wall,

- Rainscreen “cladding” or ventilated facades, and

- Cross Laminate Timber (CLT)

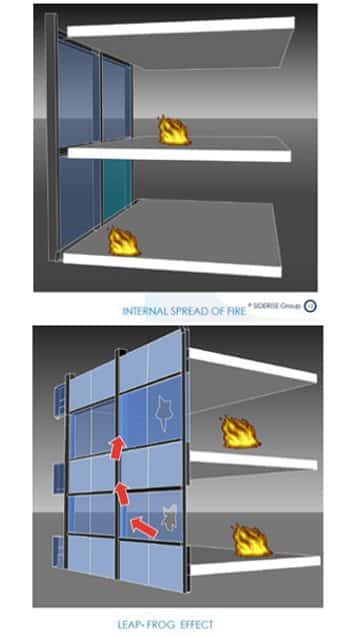

1. Curtain Wall Type Buildings

Curtain wall is defined in our NCC as a non-load bearing external wall that is not a panel wall. I will deal with panel walls later. Curtain wall construction has been with us for a very long time; we all recognise the large, glazed curtain wall buildings which are prevalent in our Australian cities. Fires have shown us that we need to provide some means to stop fire from spreading up and between the floor slab edge and the perimeter of the curtain wall assembly itself, and also to avoid leapfrogging from level to level. The slab edge fire stopping is termed perimeter fire stopping or slab edge fire stopping, to differentiate it to cavity barriers which are reserved for use in cladding systems, not curtain walls. Typically, the perimeter fire stopping works together with a spandrel to provide some fire resistance for the slab to glazed curtain wall interface.