cladding

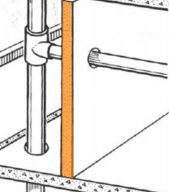

Cavity barriers for both horizontal and vertical cavities behind Rainscreen Cladding. Horizontal cavities must allow for drainage and ventilation.

Rainscreen Cladding

Cavities behind Rainscreen Façades must be correctly fire-stopped. Trafalgar Fire is proud to bring the Siderise range of fire-stopping solutions for cavities behind cladding to the Australian market.

RAINSCREEN CLADDING

Cavities behind Rainscreen Façades must be correctly fire-stopped. Trafalgar Fire is proud to bring the Siderise range of fire-stopping solutions for cavities behind cladding to the Australian market.

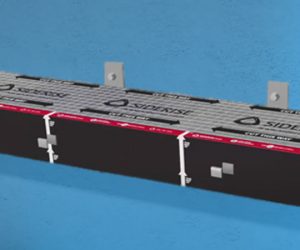

Horizontal Cavity

Open-state cavity barriers allow ventilation within a cavity under cold (normal) conditions and close the cavity under fire conditions. Such cavity barriers commonly comprise intumescent materials that can be activated at elevated temperatures (typically about 180 – 200°C). The intumescent materials continuously expand and seal the cavity gaps whilst remaining in place and withstanding the fire conditions for a considerable period.

Ventilated cavities require vertical air circulation under normal conditions whilst also allowing moisture to drain from the cavity. Horizontal cavity barriers are therefore, required to be open-state.

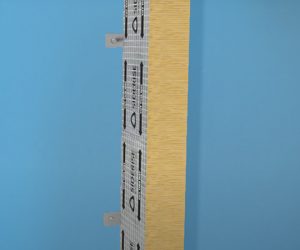

Vertical Cavity

Closed-state cavity barriers completely fill the cavity void at all times and are compressed between the inner surface of the outer wall element and the outer surface of the inner wall element.

This type of cavity barrier can be used where they do not adversely affect the required cavity ventilation, such as closing the edges of an opening.

Closed-state cavity barriers can be tested using Australian Standard. To maximise the locally available products which can be used, closed- state barriers are required to conform to AS1530.1 and AS 1530.4.

Relevant Systems

Siderise RH

Cladding systems are often referred to as rainscreens or ventilated facades. The Siderise RH open state Horizontal cavity barriers allow drainage and ventilation whilst utilising intumescent material to seal in the advent of fire.

Relevant Systems

Siderise RV

The Siderise RV vertical cavity closed state cavity barriers complete the fire-stopping SYSTEM. The fast, clean and easy systems exceed the requirements of NCC and allow proven world’s best fire protection for new buildings and recladding of buildings alike.

New Cladding Projects

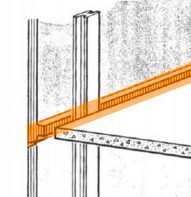

New projects require compliance with NCC Section J (Energy Provisions) which requires thermal insulation within the cavities behind the cladding. This creates a large slab edge to cladding gap which needs a special wide cavity barrier solution.

RH

Cladding systems are often referred to as rainscreens or ventilated facades. The Siderise RH open state Horizontal cavity barriers allow drainage and ventilation whilst utilising intumescent material to seal in the advent of fire.

RV

The Siderise RV vertical cavity closed state cavity barriers complete the fire-stopping SYSTEM. The fast, clean and easy systems exceed the requirements of NCC and allow proven world’s best fire protection for new buildings and recladding of buildings alike.

Recladding Projects

Recladding buildings is something we are all very conscious of from all the media exposure. Trafalgar Fire is proud to offer cost-effective and fully fire-tested cavity barrier systems to help provide a safe overall cladding system for existing buildings, including the Siderise RH intumescent strip-only solution.

RH Intumescent Strip

The Siderise RH intumescent strip only solutions allow for effective fire stopping for very small openings in the order of 20 to 50mm. The fast, clean and easy systems exceed the requirements of NCC and allow proven world’s best protection against fire for new buildings and recladding of buildings alike.

Documents and Resources

We’re proud to be making passive fire protection easier every single day. Our extensive range of resources have been written, developed, or sourced by Trafalgar Fire’s experienced team of passive fire professionals to help you better understand our systems, products, and the passive fire industry as a whole.

Check out the latest installation and product videos, articles, and case studies for Cavity Barriers applications.

Siderise RH Ventilated Rainscreen Cladding Technical Manual

Siderise RH and RV Cavity Barriers Product Info

Siderise Open State Cavity Barriers

Siderise CW-FS Curtain Wall Technical Manual

Playlist

Frequently Asked Questions

At Trafalgar Fire, we’re dedicated to making passive fire easier for you. To save you some time, we’ve answered a collection of Frequently Asked Questions about Cavity Barriers applications.

If you have any additional questions, our Technical Team is here to help.

TWRAP™ (or FyreWrap®) will need to be wrapped around the FyreBOX™ to achieve an insulation rating. Contact Trafalgar Fire for installation details and refer to our YouTube channel for installation videos.

Yes, refer to the FyrePEX HP Technical Manual for details on approved cables.

Yes, intumescent sealants require the perfect volume of sealant to expand and perform appropriately.

Using FyreSHEATH removes the need for larger openings.