Understanding Different Fire Collars

Stack V/S Floor Waste Applications

Introduction

It is sad to see the number of existing buildings where the wrong type of cast-in fire collar has been used and the strata needs to spend money to upgrade their building to comply with fire regulatory requirements.

For us well versed with fire testing methods, we understand the difference in terms of fire hazard and fire mitigation when we compare and contrast standard Drain, Waste water and Ventilation pipes (DWV) passing through Fire-Rated Concrete Floor Slabs, to a floor waste (FW), or grille and trap also passing through a fire rated concrete floor slab.

Hopefully reading this, you will be able to understand the difference between these applications, and be able to select, design, identify or certify the correct type of fire collar system for all different plastic pipe plumbing services that pass-through fire rated concrete floor slabs.

Definitions

To assist in reading this article and understand it better, the following definitions have been provided:

Fire Rating – a period of fire resistance to stop fire and its effects passing from one side of a fire barrier to another; in terms of Australia and the NCC or BCA, this is known as an FRL (Fire Resistance Level).

NCC – Australian National Construction Code

BCA – Building Code of Australia (renamed as the NCC)

DWV – Drain-Waste-Vent Systems are used in plumbing to allow air to enter the plumbing system to maintain proper pressure to enable the removal of sewage and greywater from a building.

FRL – Fire Resistance Level, the fire rating requirement required by the NCC and BCA, incorporating structural adequacy, integrity and insulation (temperature rise on the non-fire side) requirements.

Integrity – part of an FRL and defined as the ability of a fire tested system to resist the passage of flames and hot gases.

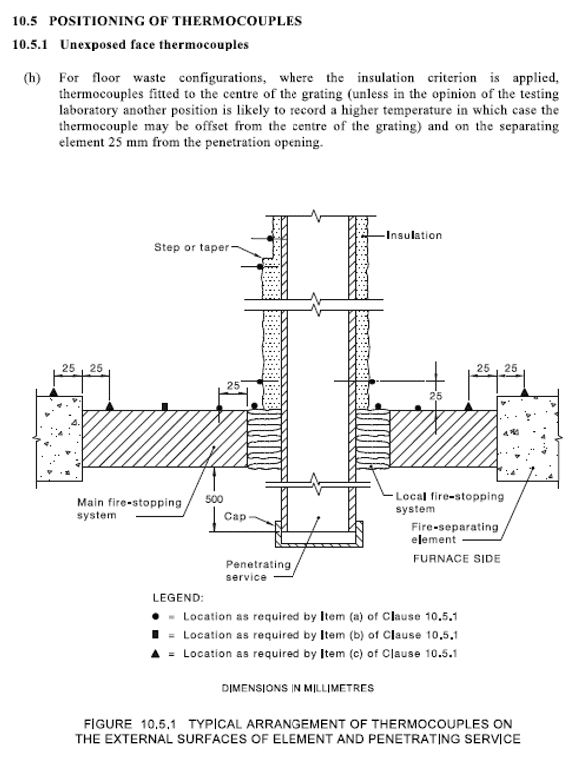

Insulation – part of an FRL and defined as the ability of a fire tested system to maintain temperatures on the non-fire side below acceptable temperature rise limits. These are measured during a fire test using thermocouples. Temperatures are measured on the non-exposed surface of the fire barrier itself (concrete slab for example), fire-stopping material in the opening and on the services that pass through or breach the fire barrier.

Structural Adequacy – part of an FRL and defined as the ability of a fire tested system to support a given load during a fire test and to maintain a strict limit of deflection and rate of deflection. Note that this part of the FRL is not applicable to service penetrations and is often represented as a dash (eg -/120/120).

Fire Stopping – The system of materials used to maintain the fire resistance of the fire barrier or so-called fire separating element of construction

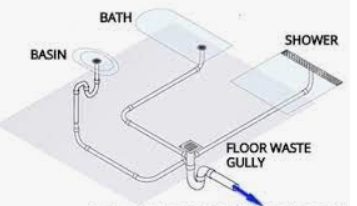

Stack Plumbing Applications – defined in AS4072.1-2005 from fire testing requirement as a through penetration whereby plastic pipes pass through the slab and extend above the floor slab. Table 4.2 of AS4072.1 defines typical applications as kitchen sink, basin, laundry sink, bath, toilet (pan) and plumbing stacks (not contained in fire rated riser shaft)

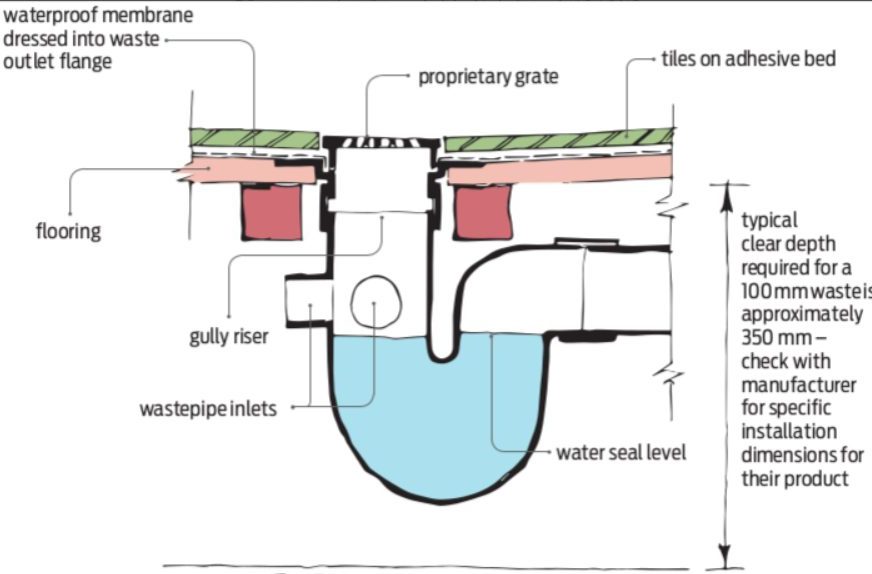

Floor Waste Plumbing Application – where there is a grate, a floor level and an associated waste trap. Table 4.2 of AS4072.1 defines typical applications as shower and floor waste at floor level. I like to think of this as an application where plastic pipes do not pass through the floor slab but terminate on the top typically with a grille.

Trap – a “U” shaped plumbing fitting that provide a liquid seal to stop the emission of sewer gases. If you look under your kitchen or bathroom sink you will recognise the U-shaped trap. Often included as part of a ‘P’ or ‘S’ shape fitting.

4-Way Riser/Gully – a plumbing fitting that allows the connection of multiple smaller pipes into one central pipe, above a water trap. Typically located under the floor below an FW grille.

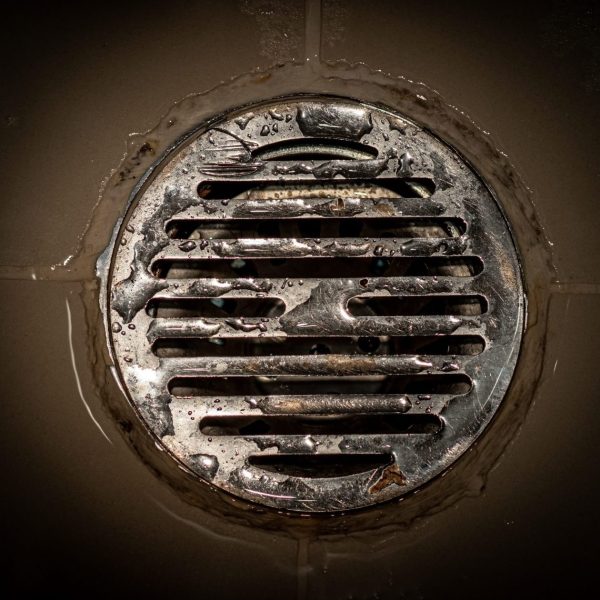

FW – Floor Waste – is a grated inlet within a graded floor intended to drain the floor surface to prevent water ponding. . It is the grille you see in the floor.

Fire Collar – typically an intumescent device installed around plastic pipes to provide a fire rating or FRL to the as-installed system. Intumescent materials swell up in the advent of fire and as the plastic pipe softens can close off the opening, limiting the spread of fire and hot gases. Some fire collars are spring-loaded for higher performance.

Cast-in Collar – A fire collar that is designed to be cast in-situ of a concrete slab for either stack or FR applications

Retrofit Collar – A fire collar that is designed to be opened/closed around an existing pipe to be retrofit into place, screwed or bolted into the fire barrier.

Fire Rated or FRL Requirements

I will discuss this in term of the barrier being a requisite fire rated concrete slab, but the same applies to so called fire rated and lightweight floor / ceiling systems, walls, riser shafts and the like.

The NCC or BCA here in Australia, requires fire rated concrete slabs to separate different floors or storey of multi-storey buildings. The fire ratings are known as the FRL.

Any openings in the fire rated concrete slabs, typically created to pass service through, or for control or movement joints, must be fire stopped. Plumbing systems, typically require many plastic pipes to pass through the fire rated concrete slabs, and the most cost effective and efficient way to fire stop these plastic pipes is to utilise a tested fire collar system.

You should take particular attention to the careful use of the word system used throughout this article when discussing fire resistance. It is important to understand that a product itself does not have a fire rating or FRL; the FRL applies to the as fire tested assembly or system.

You might be thinking, how do we determine an FRL for a system; this is done by full scale fire testing and in Australia, the fire test method required by our NCC or BCA is currently AS1530 Part – 2014.

The NCC also requires compliance with AS4072.1-2005; which complements AS1530.4-2014 and provide guidance for the minimum acceptable levels of fire testing requirements and strict rules for only minor variations from as fire tested systems.

NCC Schedule 5 also provide additional rules for minor variations from fire test systems.

Sadly, many systems being promoted in the market do not comply with AS4072.1-2005 and therefore do not comply with the NCC or BCA. Simply doing a fire test to AS1530 Part 4 with one fire barrier type, one size of plastic pipe for example, is often not enough to sell products and claim ultimate compliance.

Understanding the Difference between Floor Waste and Stack Fire Performance

Please refer to the definitions of:

- Floor Waste Plumbing Application

- Stack Plumbing Applications

Floor Waste Plumbing Applications

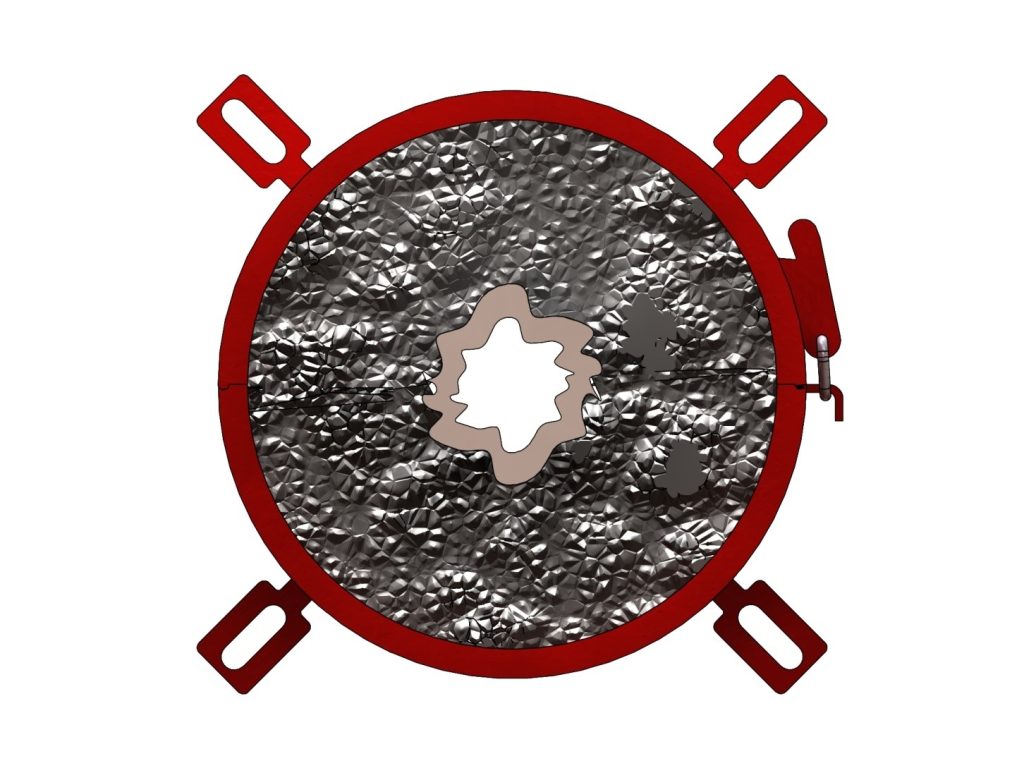

In layman’s terms, if there is a grille at floor level, as a so-called floor waste in other words, the fire testing requirements are different and more onerous. Conventional intumescent (only) collars cannot achieve the requisite insulation criteria of the FRL. The intumescent cannot close off completely, quick enough before the plastic pipes soften and allow hot gases to flue through the opening, making the grille and surrounding area to get very hot very quickly. This poses a hazard in practice, as hot gases will pass through and can quickly ignite adjacent combustible surfaces like towels, mats or sleepwear which are often seen on floor waste grilles. To pass the fire testing on floor waste plumbing applications a spring assisted fire collar is necessary.

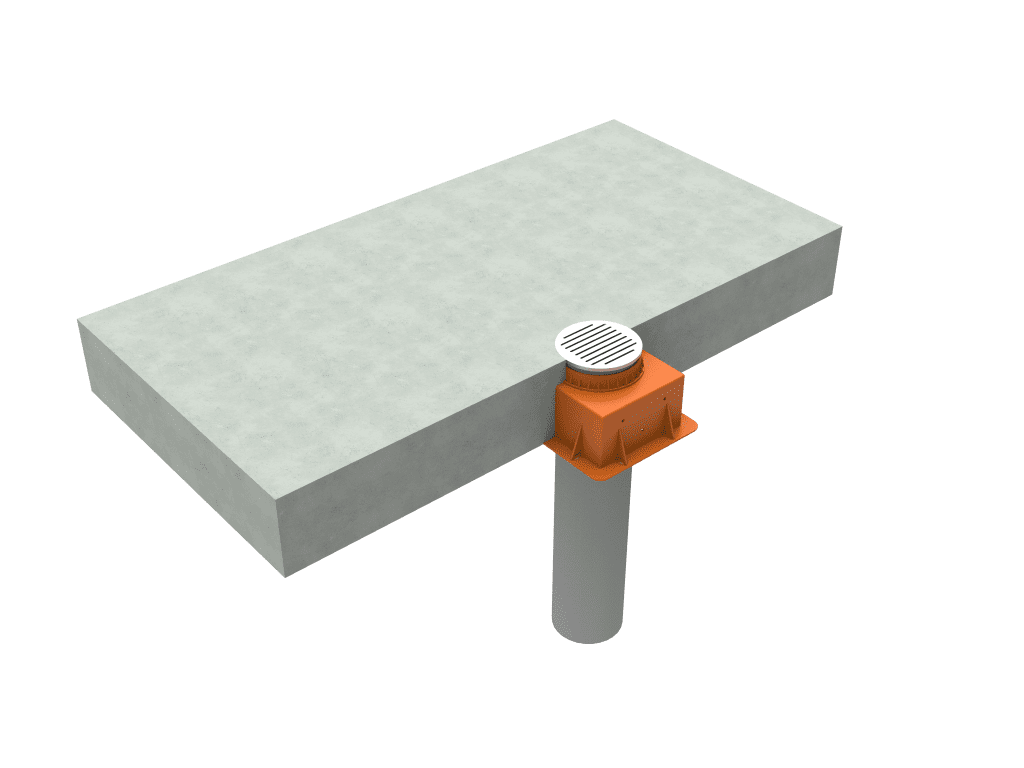

Trafalgar offers a fully patented cast-in floor waste collar. This is easily recognisable as it is rectangular in shape and made in our characteristic orange colour.

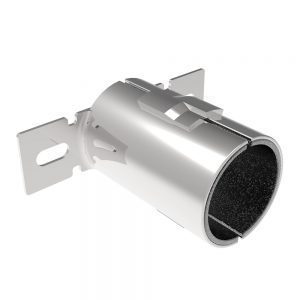

Trafalgar also now offers a retrofit floor waste fire collar, called BladeRUNNER. The BladeRUNNER is supplied in two halves with a slim line design to fit into the limited space above the water trap and can be used to upgrade penetrations where stack cast-in collars have been used incorrectly for a floor waste application.

The collar features a spring-loaded blade and an intumescent cassette to slice and close under fire conditions.

Stack Plumbing Applications

Again, in layman’s terms, if the plastic pipe passes through the slab, for a kitchen sink, basin, laundry sink, bath, toilet (pan) and plumbing stacks, a standard or intumescent (only) stack collar can typically be used. These usually do not require springs.

Trafalgar’s Cast-in stack collars are again in our characteristic orange colour. Our cast-in stack collars in both low-top and high-top variants as so plumbers prefer one to the other for ease of installation and what they are used to doing.

Trafalgar also has a range of retro-fit options for stack pipe applications using the orange FyreCOLLAR Premium Hinged Retro Fit collar ranging from 25 to 150mm in size to suit the nominal pipe size.

-

FyreCOLLAR Premium Retrofit

- Select options This product has multiple variants. The options may be chosen on the product page

-

FyreCOLLAR Mixed Services

- Select options This product has multiple variants. The options may be chosen on the product page

-

FyreCOLLAR Conduit

- Select options This product has multiple variants. The options may be chosen on the product page

Important compliance attributes from AS1530 Part 4- 2014 & AS4072.1-2005

Stack Plumbing Applications – No Spring in the Fire Collar!

- Plastic pipe passes from one side of a concrete slab to the other

- 2000mm of plastic pipe must extend above the concrete slab during fire testing

- All PVC pipe sizes must be fire tested including small conduits

- If joints or elbows are to be inside the collar body they must be fire tested separately

- Different plastic pipe materials require fire testing; eg HDPE and proprietary brands like Raupiano, and DB Blue for example.

- Both integrity and insulation FRL criteria must be achieved to match the FRL of the concrete slab

- Intumescent (only) collars can typically meet FRL requirements

- Applications include a kitchen sink, basin, laundry sink, bath, toilet (pan) and plumbing stacks

Floor Waste Plumbing Applications – Spring-Assisted Fire Collar is Necessary!

- A metal or plastic grille is incorporated on the top of the concrete slab

- If the grille is intended to be installed with waterproofing items like plastic puddle flanges, they should also be tested as part of the system

- Thermocouples measuring insulation are placed directly on the grille during fire testing

- Each size of PVC pipe must be fire tested but in Australia typically 100mm pipe is used in floor waster applications

- If joints or elbows are to be inside the collar body they must be fire tested in there

- Different plastic pipe materials require fire testing; eg HDPE and proprietary brands like Raupiano, and DB Blue for example.

- Both integrity and insulation FRL criteria must be achieved to match the FRL of the concrete slab

- Spring-assisted intumescent fire collars as necessary

- Applications include showers and floor waste (grilles) at floor level

Identifying Trafalgar Cast-In Collars from Below for Ongoing inspections

Trafalgar Stack Collars are round and orange.

You should see a galvanised steel ring inside the collar and if you look carefully the black intumescent material and/or a silicone/rubber smoke gasket.

You should also check that the pipe is supported correctly to the slab above adjacent to the fire collar.

Trafalgar Floor Waste Collars are rectangular and orange.

There will be some galvanised shutter plates and you will not see the concealed intumescent and spring assembly.

The fully patented Trafalgar design avoids pockets where springs can be fouled by concrete debris and allows for the

You should also check that the pipe is supported correctly to the slab above adjacent to the fire collar.

AS4072.1

AS1530.4

Are They as Simple as Many Think?

Introduction

There is more to compliance than just whacking a fire collar on a plastic pipe and walking away. This article is written to assist those working with fire collars understand a little bit more about them; that is what they are, what they do, how and why they are fire tested, and the different variable which must be considered when selection a fire collar or a compliant installation.

What is a fire collar?

Fire collars or some would say “firestop collars” are used to protect openings where plastic pipes pass through fire barriers.

A fire collar contains a black graphite-based material inside its body, which when exposed to heat swells up to around 30 times its original volume, in the process filling the whole where the plastic pipe is, as the plastic pipe softens and melts from the heat of the fire. This action of swelling up and “choking” the plastic pipe closed, is called intumescence and therefore the graphite-based material is an intumescent material.

Fire Testing Requirements

The National Construction Code (NCC), which many of us will remember by its former name, the Building Code of Australia or BCA, requires all services that pass through fire building elements such as walls, floor slabs, shafts or ceilings, to main the fire rating of the building element in question.

The fire rating is referred to as an FRL; short for the Fire Resistance Level.

FRL’s are determined from actual fire testing at registered fire test laboratories and we have a few important Australian Standards that provide the method and rules for fire testing of plastic pipes.

The test method is AS1530 Part 4 and the rules for fire testing are covered in AS4072.1; by rules I mean the number and type of fire tests that are required and the applications, materials and sizes of pipes that need to be addressed by the manufacturer of a fire collar.

Seven (7) helpful items to verify to help ensure fire collar compliance with the NCC / BCA

1.Fire testing results are specific to the building element type

Different fire testing is required for the following building elements:

- Floor slabs; be careful to check the minimum thickness of slab approved for each brand of collar

- Fire rated ceiling; this is a difficult one to understand as there is an additional fire requirement for ceiling cavities, called the Resistance to Incipient Spread of Fire, RISF; get help from the consultant or manufacturer with collars on fire rated ceilings

- Fire rated plasterboard walls; different testing is required for single and double layer wall types; that is for 60, 90 and 120 minute fire rated “pink” plasterboard wall types

- Fire rated plasterboard shafts; these are constructed differently than walls and care must be taken to check that fire test data exists for shaft wall constructions.

- Block and brick walls

- Proprietary walls & services shafts require their own fire testing; some examples include SpeedPanel, Walsc, Hebel and Pronto.

2. Fire testing is required for each plastic pipe material type and wall thickness

Quite often we only think of uPVC, but there are many different plastic pipes being used for plumbing applications now:

- HDPE, PP, PE

- PEX

- PEX-AL-PEX

- Special proprietary ones like Valsir Triplus, Aquaheat, SilentFlow etc

3. Each pipe size requires fire testing

4. Fire testing is required with and without fitting inside the fire collar

5. For floor slabs, different fire testing is necessary for a floor waste and for a pipe that continues through the slab; often referred to as a stack application.

6. The opening size and configuration around the plastic pipe is important also in term of fire testing and approved systems

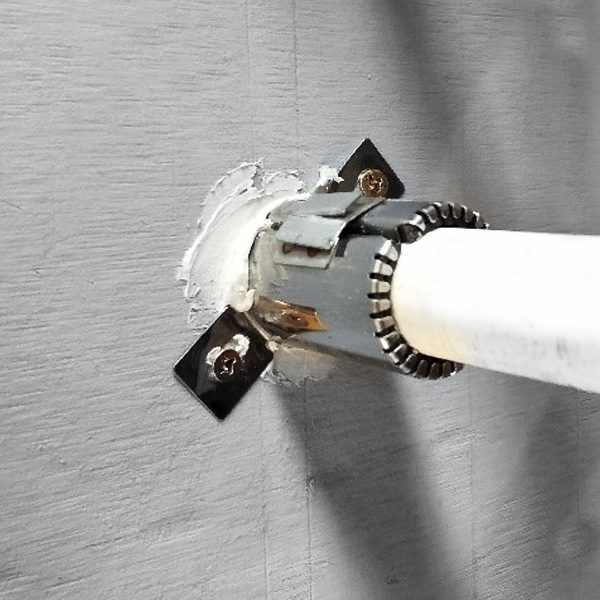

7. The use of the as fire tested and correct fixing are IMPERATIVE for fire collars that are attached after the pipe is in situ

Main Types of Fire Collars

There are some fire collar types that are worthy of mention:

1.Cast-in Floor Slab Collars

So-called, because these fire collars are fixed to formwork prior to the concrete being poured, and are cast in situ once the concrete is poured; forming an opening complete with the cast-in fire collar in situ when the formwork is removed.

As discussed earlier there are two main and very different types of cast-in fire collars

Stack (circular) and Floor Waste (square)

2.Retrofit fire collars

These are applied after the pipe is in the opening through the fire wall. They can open up and be placed around the pipe, and then fixed to the underside of a floor slab or ceiling, or to BOTH sides of a vertical wall or shaft.

3.Conduit collars

These are smaller collars designed and fire tested specifically for small plastic conduits.

Yes, fire ratings and FRL requirements apply to every opening and service that passed through any fire rated building element required; even for small opening, contrary to the wife tales that often get shared around the plumbing industry.