John Rakic

John Rakic is the proud Owner and Managing Director of Trafalgar Group with over 20 years of experience in the passive fire industry.

There is more to compliance than just whacking a fire collar on a plastic pipe and walking away. This article is written to assist those working with fire collars understand a little bit more about them; that is what they are, what they do, how and why they are fire tested, and the different variable which must be considered when selecting a fire collar or a compliant installation.

This is just a snippet of the full article. To read the entire article, download the pdf today.

Table of Contents

What Is A Fire Collar?

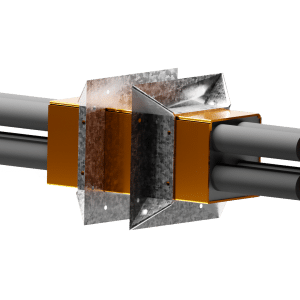

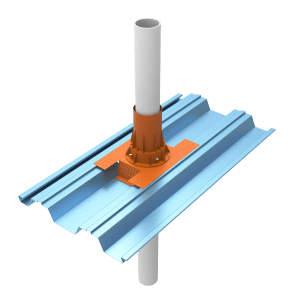

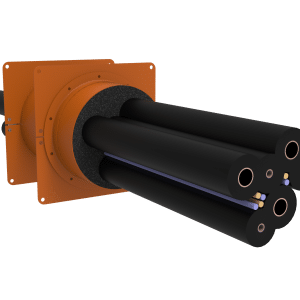

Fire collars or some would say “firestop collars” are used to protect openings where plastic pipes pass through fire barriers.

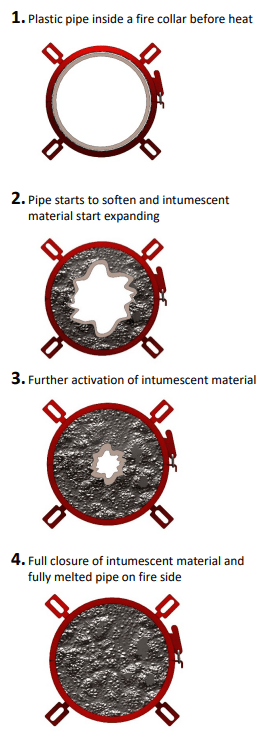

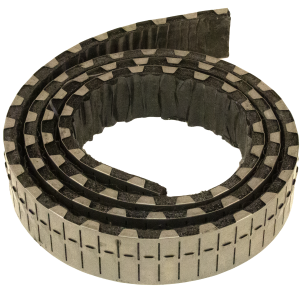

A fire collar contains a black graphite based material inside its body, which when exposed to heat swells up to around 30 times its original volume, in the process filling the whole where the plastic pipe is, as the plastic pipe softens and melts from the heat of the fire. This action of swelling up and “choking” the plastic pipe closed, is called intumescence and therefore the graphite-based material is an intumescent material.

Fire Testing Requirements

The National Construction Code (NCC), which many of us will remember by its former name, the Building Code of Australia or BCA, requires all services that pass through fire building elements such as walls, floor slabs, shafts or ceilings, to

main the fire rating of the building element in question.

The fire rating is referred to as an FRL; short for the Fire Resistance Level.

FRL’s are determined from actual fire testing at registered fire test laboratories and we have a few important Australian Standards that provide the method and rules for fire testing of plastic pipes.

The test method is AS1530 Part 4 and the rules for fire testing are covered in AS4072.1; by rules I mean the number and type of fire tests that are required and the applications, materials and sizes of pipes that need to be addressed by the manufacturer of a fire collar.