Trafalgar Fire are committed to partnering with world leading companies like Siderise to adopt their factory-patented Curtain Wall Fire Stop (AKA cavity barrier) systems and bring to the local Australian Market.

With passive fire protection historically being an afterthought in the building industry, this project highlighted what can be achieved with a well-designed and executed passive fire protection system installed at the slab edge behind the curtain wall.

The Challenge

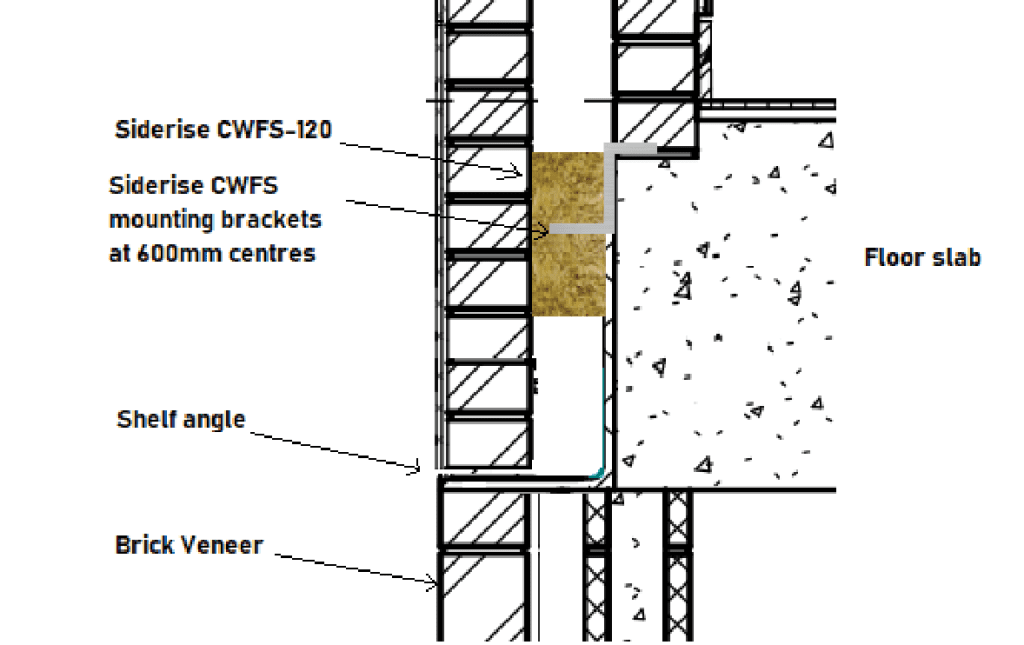

The challenge was the builder had only used traditional methods of fire stopping at the slab edge where continuous metal angle or flashing is installed along with loose stone wool batt which is laboursome and not fit for purpose.

Cavities that exist between an external wall and an internal fire-rated barrier must be packed with a material that provides:

- Fire separation

- Smoke seal

- Acoustic rating

- Thermal rating (efficiency)

- Resistance to movement

The Delivery

Trafalgar Fire has tested Siderise CWFS locally to Australian standards, and in conjunction with additional third-party approvals provided a fit-for-purpose cavity barrier system to meet all requirements of the building codes (NCC, specifically NCC C2.6a). The Siderise CWFS was installed on-site and inspected with the free inspection app that provides certainty and the product warranty for a safer and more compliant building.

PDF Download

Click the button below to download this case study for easy reading and printing.