John Rakic

John Rakic is the proud Owner and Managing Director of Trafalgar Group with over 20 years of experience in the passive fire industry.

This is just a snippet of the full article. To read the entire article, download the pdf today.

Table of Contents

What does NCC 2019 say regarding pipe insulation?

For me it feels like yesterday that energy efficiency was voluntary, but with each iteration of the NCC – now every three years – the provisions get more stringent.

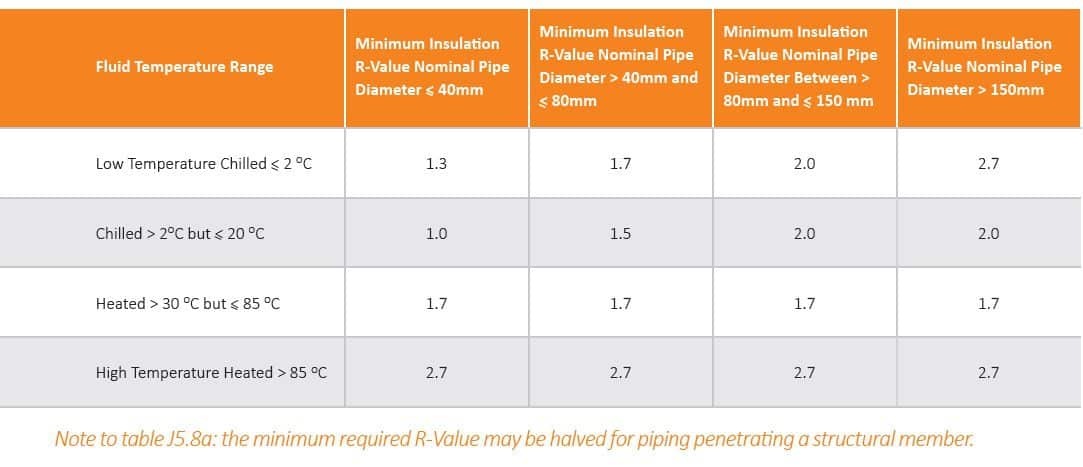

Section J5.8 of the NCC has some prescriptive requirement for energy efficiency for pipe work that carries heated or cooled fluids. These provisions require the addition of insulation materials or lagging to the pipe work. The NCC requires mandatory thermal resistance values (or R values) for these insulation materials. The thickness of the material will vary depending on the insulation material used, the size of the piping, and the temperatures range of the fluid they are carrying.

What does that mean to passive fire protection?

Put simply, combustible insulation materials that provide the requisite R values are now put on all this pipe work. These materials provide a new challenge to passive fire protection systems.

Engineered high-performance intumescent materials are required to quickly close-down or fill up the openings formed by the shrinkage and melting of the insulation materials in fire conditions. Intumescent materials are materials that expand or swell rapidly in fire conditions and allow us to use plastic materials for services. The most common form of intumescent device is a fire collar, used to protect plastic plumbing pipes in fire conditions.

What pipe and insulation materials are we seeing?

Most HVAC&R pipes are copper; they used to be bare copper before Section J requirements and of course now they are insulated copper pipes.

There are two main types: those being factory manufactured pre-insulated pair coils, and copper pipes with added insulation materials.