“Without over complicating things, this ductwork needs to turn of automatically when a building is in fire mode.

This is to stop the heating & air conditioning system spreading smoke to all parts of the building.

Where the ductwork passes through a fire barrier, there is a requirement for a fire damper.

Do you think when they hear the term fire compartment wall, do they think or expect this barrier is safe for fire spread and smoke spread?”

John Rakic

John Rakic is the proud Owner and Managing Director of Trafalgar Group with over 20 years of experience in the passive fire industry.

This is just a snippet of the full article. To read the entire article, download the pdf today.

Our commercial and multiple story residential buildings are a spider web of ducts, pipes, cables and other services providing HVAC&R (Heating, Mechanical Ventilation, Air Conditioning and Refrigeration) for comfort, safety, and overall amenity of occupants.

With the increased scrutiny of energy conservation with escalating power costs and the very real need to be more sustainable and reduce our carbon footprint, this creates many new and modern-day challenges for so called passive fire protection.

We will discuss some old and more recent challenges for different HVAC&R systems, both components, and some advances in fire stopping & fireproofing materials and Trafalgar’s Fire systems available to designers and building service engineers. apartment, or commercial building.

DEFINITIONS

Passive Fire Protection

The division of buildings in fire and/or smoke containment compartments is designed to limit the spread of fire and/or smoke from one part of a building to another. It consists of fire and/or smoke barriers such walls, floors, ceilings and riser shafts which have a Fire Rating (FRL) or a Smoke Containment requirement.

By necessity these fire and/or smoke barriers have many ducts and services in the context of HVAC&R that need to pass through them. The challenge for building services engineers is to ensure that these ducts and services do so without compromising the fire and smoke movement for both life safety of occupants and fire fighters, but for reduction on damage to the building and the business in the event of a serious fire.

Fire Stopping

The correct protection of openings for services (& movement joints) to maintain the FRL of the fire and/or smoke barriers. Under the National Construction Code / Building Code of Australia (NCC/BCA) this requires fire test to AS1530 Part 4 – 2014 to achieve system FRL’s.

Fireproofing

For the purposes of this document, fireproofing relates to fire protection of ductwork required under AS/NZS1668.1 for fire and smoke control purposes.

In my own personal definition, it would also include fireproofing of structural steel elements in a building.

Smoke Containment & Smoke Stopping

Smoke walls are often required in hospitals and aged care facilities and openings for services (& movement joints) such like fire stopping require smoke stopping.

At present the NCC/BCA do not quantify these in terms of smoke ratings for systems under smoke or air leakage testing akin to fire ratings and FRL’s.

THE PLETHORA OF HVAC&R DUCTS AND SERVICES IN OUR BUILDINGS

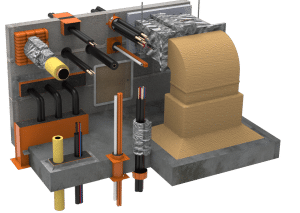

This diagram from part of one of our Trafalgar Fire HVAC&R trade specific technical manual for passive fire and

smoke containment. It is available for FREE download on this web site link; https://tfire.com.au/hvacr/

You can see ducts passing through fire and/or smoke barriers in both a vertical run and horizontal run; along with many different pipes; many of which under todays regulations are lagged with thermal insulation for conservation of energy. These might be insulated copper for example, but with the price of copper being so high, we are seeing some shifts to steel, thinner gauge stainless steel and plastic material, again with applied lagging.

In many cases electrical cables also are passed through the same opening, and we see the requirement to provide fire stopping for so called pair coil bundles for example; one or more passing through the same opening in a fire and/or smoke barrier.

DUCT WORK OR DUCTING

Over the last 20 or so years I have seen confusion and non- compliances pertaining to ducts

and associated fire & smoke dampers. If one understands the basic design principles, one can easily navigate what might look very confusing and complicated. The key is to answer the following question: What is the duct used for in the building?

HEATING & AIR CONDITIONING?

Most duct work will be for heating & air conditioning systems and moving air from one area to another for the

comfort of the occupants. In winter we want it warmer and in our very hot summers, we want it colder and some “aircon” at play.

Without over complicating things, this ductwork needs to turn of automatically when a building is in fire mode.

This is to stop the heating & air conditioning system spreading smoke to all parts of the building. Where the ductwork passes through a fire barrier, there is a requirement for a fire damper. A fire damper is a failsafe means of protecting these openings where the ducts are passing vertically or horizontally through a fire barrier. These fire dampers can be mechanical and incorporate a fusible link, or intumescent and when the heat in the duct during a fire increases, the fusible link melts and the mechanical damper closes, or the intumescent slats swell up and close of the opening in the duct.

ACTIVE SMOKE CONTROL MEASURES?

These ducts form part of complicated smoke control measures used for fire protection purposes in a building. For me I try and simplify things into those that blow, and those that suck (no pun intended). A more engineering definition is pressurisation systems that blow air & exhaust systems that suck air. These smoke control duct systems cannot and do not have fire dampers in the opening through fire barriers as these would render the pressurisation or exhaust system inactive. For this reason, these ducts need to be fire rated and therefore will typically have an applied fireproofing materials and requisite fire rating & FRL. AS/NZS1668.1 is where all the design criteria for fire & smoke control systems live.